It is best to install bearings on presses (hydraulic presses, screw presses), because the bearings are not subject to knocking and will not damage the bearings and shafts. Whether the bearing is installed well or not will affect the accuracy, life and performance of the bearing. Therefore, please fully study the installation of bearings, and carry out bearing installation in accordance with the operating standards including the following items.

The installation of the bearing should be determined according to the bearing structure, size and the matching properties of the bearing components. The pressure should be directly applied to the end face of the tightly fitted ferrule, and the motor stator should be pressed into the motor casing for equipment installation. Bearing installation generally adopts the following methods:

When the inner ring of the bearing is tightly fitted with the shaft, and the outer ring is loosely fitted with the bearing seat hole, the bearing can be pressed onto the shaft with a press first, and then the shaft and the bearing are put into the bearing seat hole together. On the end face of the inner ring of the bearing, the inner diameter of the assembly sleeve should be slightly larger than the diameter of the journal, and the outer diameter should be slightly smaller than the rib of the inner ring of the bearing to avoid pressing on the cage. When the outer ring of the bearing is tightly fitted with the housing hole, and the inner ring is loosely fitted with the shaft, the bearing can be pressed into the housing hole first. At this time, the outer diameter of the fitting tube should be slightly smaller than the diameter of the housing hole. If the bearing ring is tightly fitted with the shaft and seat hole, the inner ring and outer ring should be pressed into the shaft and seat hole at the same time, and the structure of the assembly sleeve should be able to press the end faces of the inner ring and outer ring of the bearing at the same time.

Thermal expansion is used to convert a tight fit to a loose fit by heating the bearing or housing. It is a common and labor-saving installation method. This method is suitable for the installation of bearings with large interference. Put the ring of the bearing or separable bearing into the oil tank to heat evenly before shrink fitting, then take it out of the oil and install it on the shaft as soon as possible. The end face of the ring and the shaft shoulder are not tightly fitted, and the axial tightening can be carried out after the bearing is cooled. When the outer ring of the bearing is tightly fitted with the bearing seat made of light metal, the heat fitting method of heating the bearing seat can be used to avoid the mating surface from being scratched. When using the oil tank to heat the bearing, there should be a grid at a certain distance from the bottom of the tank, or the bearing should be hung with a hook. The bearing should not be placed on the bottom of the tank to prevent impurities from entering the bearing or uneven heating. There must be a thermometer in the tank. The oil temperature is strictly controlled to prevent the tempering effect that reduces the hardness of the ferrule.

In order to meet the strict positioning and rotation requirements of gears, high-speed rolling bearings, shafts and bearing housing holes need to adopt interference fit. When the bearing interference is too small, the bearing will creep and fail. When the bearing interference is too large, the workpiece will be scratched when the hydraulic press is used for cold pressing.

When installing the bearing, the following issues should be paid attention to: Pay attention to keep the centerline of the press rod and pressure head coincident with the centerline of the installation sleeve or the centerline of the shaft, so as to prevent the shaft or bearing from tilting.

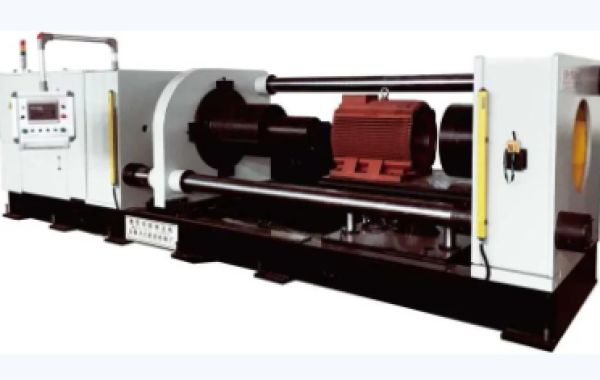

The motor horizontal bearing press adopts a horizontal structure, which solves the problem of poor stability of the motor stator of the vertical press equipment. The machine tool is fully numerically controlled and electronically controlled, which can accurately control the distance of the stator voltage entering the motor casing, thereby minimizing the number of fixtures and saving costs.