Are you looking for a cost-effective solution for precision stamping parts in mass production? Look no further than Wuxi adaqiao Machinery, your go-to supplier for all your precision stamping needs. Precision stamping is the process of cutting and shaping metal sheets into various shapes and sizes with high accuracy and consistency. It offers numerous benefits such as faster production times, lower labor costs, and higher quality products. However, it also comes with its own set of challenges that can be daunting to overcome. In this blog post, we'll explore the world of precision stamping and how Wuxi adaqiao Machinery can provide you with affordable solutions tailored to your specific needs.

What is precision stamping?

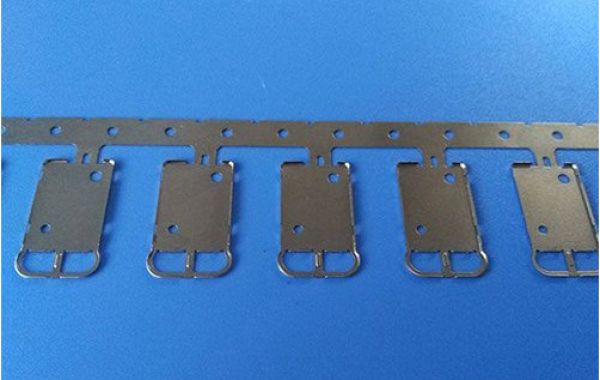

Precision stamping is a manufacturing process that involves cutting and shaping metal sheets into precise shapes with high accuracy and consistency. This process uses various tools such as dies, punches, and presses to form the desired shape.

One of the key advantages of precision stamping is its ability to produce large quantities of identical parts quickly. It's an ideal solution for mass production industries such as automotive, aerospace, and electronics.

The method starts by feeding flat metal sheet material through a press machine where it undergoes several stages of punching or blanking to create smaller parts before being formed into complex shapes. The finished product can be further processed through additional finishing techniques like plating or polishing.

Precision stamping also has the advantage of producing minimal waste since it utilizes computer-aided design (CAD) software to optimize material usage. Moreover, precision stamped parts are typically stronger than their counterparts produced through other methods like casting or welding due to how they are created from one single piece without any joints or seams.

Precision stamping offers numerous benefits for those in need of mass-produced metal products that require high levels of accuracy and consistency while minimizing costs associated with labor-intensive processes.

The benefits of precision stamping

Precision stamping is a manufacturing process that involves the use of specialized machinery to produce high-quality metal parts with tight tolerances. There are several benefits of precision stamping for mass production.

Firstly, precision stamping allows for the creation of complex and intricate parts with consistent accuracy. This level of precision ensures that each part produced meets the required specifications and performs its intended function effectively.

Secondly, precision stamping is highly efficient and cost-effective compared to other manufacturing processes. It can produce large quantities of parts in a short amount of time without sacrificing quality or accuracy, reducing overall production costs.

Thirdly, precision stamping offers versatility in material selection as it can work with a wide range of metals including stainless steel, brass, copper, and aluminum among others. The ability to choose from different materials makes it possible to create custom parts suitable for specific applications.

Using precision stamping results in minimal waste during production since only the required amount of material is used. This reduces raw material expenses while also minimizing environmental impact by reducing scrap generation.

The benefits offered by precision stamping make it an ideal solution for producing high-quality metal components at scale efficiently and cost-effectively.

The challenges of precision stamping

Precision stamping is undoubtedly a cost-effective and efficient manufacturing process, but it also comes with its own set of challenges. One significant challenge is the need for high precision in every single step of the process. Any deviation from the specifications can result in faulty parts that cannot be used.

Another challenge faced by manufacturers during precision stamping is material selection. The raw materials used must be durable enough to withstand the force applied during stamping while being malleable enough to take on any required shape without cracking or breaking.

Additionally, maintaining consistency throughout mass production can prove difficult as even minor variations in temperature or pressure could lead to inconsistencies in the final product. This requires skilled professionals who are trained and experienced enough to detect problems early on before they escalate into bigger issues.

Ensuring that all safety regulations are met during precision stamping operations presents yet another challenge. Machinery must operate within certain parameters, and workers must adhere strictly to safety protocols at all times.

Despite these challenges, companies like Wuxi AdaQiao Machinery have excelled in providing cost-effective solutions for their clients while maintaining quality standards through strict adherence to best practices and continuous improvement initiatives.

Cost-effective precision stamping parts solutions

When looking for a precision stamping parts supplier, cost-effectiveness is always a top priority. Fortunately, there are several solutions that can help you save on costs without sacrificing quality.

One such solution is utilizing progressive tooling in the stamping process. Progressive tooling allows multiple operations to be performed in one pass through the machine, reducing labor and material costs.

Another solution is utilizing high-speed stamping machines. These machines are capable of producing parts at a faster rate than traditional machines, meaning more parts can be produced in less time, ultimately reducing overall production costs.

Choosing the right materials and processes can also contribute to cost savings. Utilizing materials with lower scrap rates or implementing secondary operations like deburring during the stamping process can reduce waste and improve efficiency.

Ultimately, working with an experienced and knowledgeable precision stamping supplier like Wuxi adaqiao Machinery can provide valuable insights into cost-effective solutions for your specific needs.

How to choose the right precision stamping supplier

When it comes to choosing the right precision stamping supplier for your mass production needs, there are a few factors that you need to consider. Here are some tips on how to choose the right supplier:

1. Look for experience: You want a supplier who has years of experience in precision stamping and can provide quality parts consistently.

2. Quality control: A good supplier should have strict quality control measures in place to ensure that all parts meet or exceed your specifications.

3. Technology and equipment: The latest technology and high-quality equipment will ensure that your parts are produced efficiently and accurately.

4. Customization options: Your chosen company should be willing to work with you to customize their services according to your specific requirements.

5. Cost-effectiveness: While cost is an important factor, it shouldn't be the only consideration when choosing a precision stamping supplier. Look for companies that offer competitive pricing without compromising on quality or service.

6. Communication skills: Good communication is essential in any business relationship, so look for a supplier who communicates clearly and promptly throughout the project.

By considering these factors, you'll be able to find the right precision stamping supplier for your mass production needs from companies like Wuxi AdaQiao Machinery at an affordable price point without sacrificing quality or reliability!

Conclusion

In summary, precision stamping is a cost-effective method for producing high-quality and complex metal parts in large quantities. With the help of advanced technology and skilled professionals, precision stamping suppliers can offer customized solutions to meet the specific needs of their clients.

When looking for a precision stamping supplier, it's essential to consider factors such as experience, reputation, quality control processes, and pricing. Wuxi adaqiao Machinery is an excellent choice for those seeking reliable and efficient precision stamping services. Their team has over 20 years of experience in the industry and utilizes state-of-the-art equipment to ensure optimal results.

By partnering with a trusted and reputable supplier like Wuxi adaqiao Machinery, businesses can benefit from cost-effective solutions that enhance productivity while reducing expenses associated with traditional manufacturing methods.

If you're interested in learning more about how precision stamping can benefit your business or have any questions regarding our services at Wuxi adaqiao Machinery, feel free to contact us today!