Are you curious about the latest manufacturing technology that is revolutionizing the industry? Look no further than precision stamping parts! These tiny components may seem insignificant, but they play a crucial role in creating everything from automobiles to medical devices. In this blog post, we'll explore what precision stamping parts are, how they benefit manufacturers, and why this technology is quickly becoming the future of manufacturing. So buckle up and get ready to discover how these small yet mighty components are changing the game for manufacturers worldwide!

What are precision stamping parts?

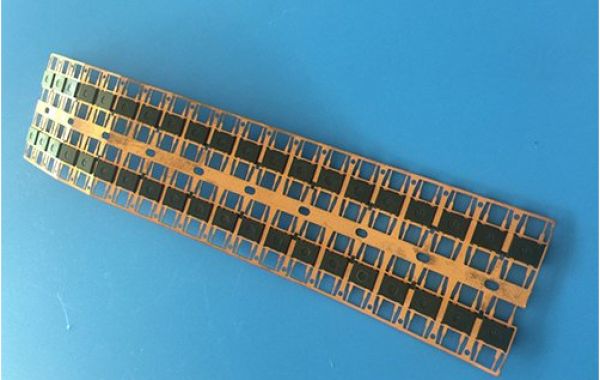

Precision stamping parts are small metal components that are created through a process called precision stamping. This process involves using a high-speed press to cut, shape, and bend metal into the desired form. The resulting parts can range in size from tiny electrical contacts to larger automotive components.

The precision of this manufacturing method is unmatched by other techniques such as casting or forging, as it allows for intricate designs with tight tolerances. This means that manufacturers can produce complex geometries with greater accuracy than ever before.

In addition to its precision, precision stamping technology offers several key benefits for manufacturers. First and foremost is its efficiency - the high-speed presses used in this process allow for rapid production of large quantities of parts without sacrificing quality.

Furthermore, because these machines operate automatically, there is less room for error and human intervention during the production process. This increases consistency and reduces waste and costs associated with reworking faulty components.

All in all, precision stamping parts are an essential component of modern manufacturing processes due to their accuracy, speed of production, and cost-effectiveness.

The benefits of precision stamping technology

Precision stamping technology has revolutionized the manufacturing industry by offering a range of benefits that traditional manufacturing methods cannot match. One of the primary advantages is its ability to create highly accurate and complex parts with consistency, speed, and cost-effectiveness.

With precision stamping technology, manufacturers can produce parts with tight tolerances for dimensions as small as 0.001 inches. This high level of accuracy enables companies to manufacture intricate designs and shapes that were previously impossible or too expensive to make using other methods. Additionally, since precision stamping processes are automated, they reduce the chance of human error and increase overall productivity.

Another benefit of this technology is its flexibility in working with different materials such as metals (stainless steel, copper), plastics (polycarbonate), and even composites (carbon fiber). Precision stamping machines can quickly switch between various materials without requiring any major adjustments or changes in settings.

Moreover, precision stamping eliminates many secondary operations such as drilling or welding required during traditional manufacturing processes. By reducing these additional steps needed for finishing products from other methods often leads to more costs spent; however with precision stamped parts there's minimal need for post-processing which results in reduced production time costs while increasing efficiency levels.

It's evident that precision stamping technology provides numerous advantages over traditional manufacturing techniques - accuracy complexity along with material flexibility being most notable ones among them.

How this technology is revolutionizing the manufacturing industry

Precision stamping technology has been a game-changer for the manufacturing industry. It has completely revolutionized the way companies produce products and parts. This technology allows manufacturers to create intricate designs with high accuracy and precision, which was not possible before.

With precision stamping technology, manufacturers can now produce high-quality parts at a faster rate than ever before. The process is more efficient and requires less labor-intensive work, saving time and money for companies.

The use of this technology in industries such as automotive, aerospace, medical devices, electronics, and telecommunications has led to significant advancements in these fields. Companies can now create complex components that are crucial for the functioning of various equipment.

Moreover, precision stamping technology also helps reduce waste by allowing manufacturers to use materials more efficiently during production. This results in cost savings while ensuring that no valuable resources go unused.

It is evident that precision stamping technology is transforming the manufacturing industry in multiple ways – from increasing efficiency to reducing costs while providing higher quality products. Its impact on different sectors will only continue to grow as new innovations emerge over time.

Some examples of companies that are using precision stamping technology

Companies across various industries are increasingly turning to precision stamping technology for its numerous benefits and advantages. One such company is Apple, which uses precision stamping parts in the production of their iPhones and other devices. The use of precise metal parts ensures that the devices are durable and have a sleek design.

Another example is BMW, which utilizes precision stamping technology in the manufacturing of their cars. By using stamped metal parts, they can achieve complex geometries with high accuracy, resulting in better performance and fuel efficiency.

The aerospace industry also heavily relies on precision stamping technology for creating lightweight yet strong components for spacecrafts. Companies like SpaceX use this technique to produce rocket engine components that can withstand extreme conditions during space travel.

Additionally, medical device manufacturers like Medtronic use this technology to create intricate components used in surgical instruments and implantable devices. Precision stamping allows them to manufacture small yet complex geometries with tight tolerances required by these types of medical applications.

Companies from various industries are taking advantage of the many benefits provided by precision stamping technology to improve product quality while reducing costs at the same time.

The future of precision stamping technology

As we move towards an increasingly automated and data-driven manufacturing industry, the future of precision stamping technology looks brighter than ever. With advancements in artificial intelligence, machine learning, robotics, and automation, we can expect to see even more complex shapes and designs being produced with greater efficiency and accuracy.

Moreover, as sustainability becomes a key concern for businesses across the world, precision stamping technology offers a promising solution. By minimizing material waste and reducing energy consumption during production processes, this technology is helping manufacturers become more environmentally responsible.

All things considered; it's safe to say that precision stamping parts are indeed the future of manufacturing technology. As companies continue to invest in this cutting-edge technology for their production processes - they will undoubtedly enjoy faster turnaround times at lower costs while producing high-quality products that meet customer specifications every time.