Nitriding is a surface hardening process that is widely used in the manufacturing industry to improve the wear resistance, fatigue strength, and corrosion resistance of metal components. The process involves the diffusion of nitrogen into the surface of the metal at high temperatures, typically between 500°C and 1100°C, in the presence of a nitrogen-rich atmosphere. The quality and efficiency of the nitriding process depend on several factors, including the type of furnace used, the atmosphere control, and the process parameters. In this article, we will focus on the benefits of using a controlled atmosphere furnace well-type nitriding furnace for streamlining your nitriding process.

What is a Controlled Atmosphere Furnace Well-Type Nitriding Furnace?

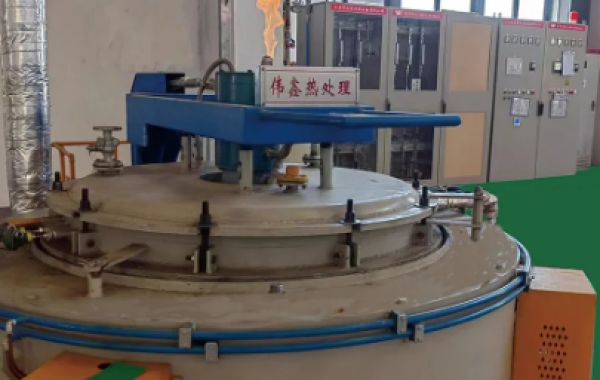

A controlled atmosphere furnace well-type nitriding furnace is a type of heat treatment furnace that is designed for the nitriding process. The furnace consists of a cylindrical chamber with a well in the center, where the metal components to be nitrided are placed. The well is surrounded by heating elements that provide the required heat to the chamber. The furnace is equipped with a gas control system that allows the user to regulate the atmosphere inside the chamber. The gas control system typically includes a gas inlet, a gas outlet, and a gas flow meter. The atmosphere inside the chamber is monitored and controlled by a thermocouple or a pyrometer.

Advantages of Using a Controlled Atmosphere Furnace Well-type Nitriding Furnace

1. Precise Atmosphere Control

One of the main advantages of using a controlled atmosphere furnace well-type nitriding furnace is the precise control of the atmosphere inside the chamber. The gas control system allows the user to adjust the composition of the atmosphere, the flow rate, and the pressure. This level of control ensures that the nitriding process is carried out under optimal conditions, resulting in a uniform and consistent nitrided layer on the metal components.

2. Improved Process Efficiency

The precise atmosphere control also improves the efficiency of the nitriding process. The controlled atmosphere furnace well-type nitriding furnace can be operated at higher temperatures and for longer periods of time, resulting in a faster nitriding process. The improved efficiency reduces the overall processing time and increases the throughput of the furnace.

3. Improved Nitriding Quality

The precise atmosphere control and improved process efficiency of the controlled atmosphere furnace well-type nitriding furnace also result in improved nitriding quality. The uniform and consistent nitrided layer on the metal components improves the wear resistance, fatigue strength, and corrosion resistance of the components. The improved quality of the nitrided components also reduces the need for post-processing, resulting in further cost savings.

Conclusion

In conclusion, acontrolled atmosphere furnace well-type nitriding furnace is an excellent investment for streamlining your nitriding process. The precise atmosphere control, improved process efficiency, reduced nitriding costs, and improved nitriding quality make the furnace an essential tool for any manufacturing operation that requires nitriding. If you are looking to improve the quality and efficiency of your nitriding process, consider investing in a controlled atmospherefurnace well-type nitriding furnace.

Jiangsu Weixin Heat-Treating Facility Ltd is a manufacturer controlled atmosphere furnace well-type nitriding furnace, including nitriding furnaces and various types of high-end heat treatment equipment. Its products are known for their precision, reliability, and efficiency, and are used in applications ranging from aerospace and automotive to medical and electronics.