Welcome to the exciting world of Proton Exchange Membrane (PEM) Electrolyzer! If you're curious about this cutting-edge technology and its potential applications, you've come to the right place. In this blog post, we will dive deep into understanding the basics of PEM electrolyzers and explore how they work their magic in producing clean energy. So buckle up and get ready for an enlightening journey through the fascinating realm of PEM electrolyzers. Whether you're a tech enthusiast or simply intrigued by sustainable solutions, there's something here for everyone. Let's embark on this electrifying adventure together!

What is a Proton Exchange Membrane (PEM) Electrolyzer?

Proton Exchange Membrane (PEM) Electrolyzers are advanced devices that play a crucial role in the production of clean and sustainable energy. They are a type of electrolyzer that utilize an innovative technology called Proton Exchange Membrane, also known as a Polymer Electrolyte Membrane.

So, what exactly is this PEM technology? Well, at the heart of every PEM Electrolyzer lies a membrane made from special polymers. This membrane acts as a catalyst to facilitate the splitting of water molecules into hydrogen and oxygen gases through an electrochemical process called electrolysis.

But how does it work? When an electric current passes through the membrane, it triggers a series of chemical reactions within the device. The negatively charged electrode attracts positively charged protons (H+ ions), while simultaneously repelling negatively charged hydroxide ions (OH-). As a result, hydrogen gas is produced at the cathode side, while oxygen gas is generated at the anode side.

One key advantage of PEM Electrolyzers is their ability to operate at relatively low temperatures compared to other types of electrolyzers. This makes them more efficient and cost-effective for industrial applications such as power generation, fuel cell vehicles, and even renewable energy storage solutions.

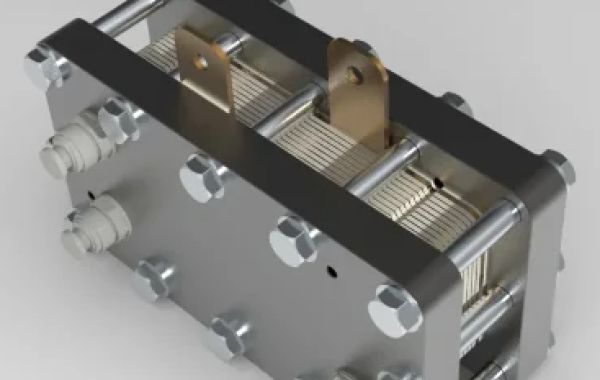

With their compact size and fast response time, PEM Electrolyzers offer great flexibility for on-site hydrogen production. Whether it's for refueling stations or remote areas with limited access to conventional energy sources, these devices provide a reliable means of generating clean fuel wherever needed.

Proton Exchange Membrane (PEM) Electrolyzers are cutting-edge devices that use specialized membranes to split water into its constituent elements - hydrogen and oxygen - using electricity. Their versatility and efficiency make them vital components in advancing our transition towards cleaner energy alternatives.

How does a Proton Exchange Membrane (PEM) Electrolyzerwork?

A Proton Exchange Membrane (PEM) Electrolyzer is a technology that plays a crucial role in the production of hydrogen gas through the process of water electrolysis. But how does it actually work?

At its core, a PEM Electrolyzer consists of two electrodes— an anode and a cathode— separated by a thin polymer membrane. When an electric current is passed through the system, water molecules are split into their constituent parts: hydrogen ions (protons) at the anode and oxygen gas at the cathode.

The key component in this process is the proton exchange membrane, which allows only protons to pass through while blocking other elements. This selective permeability ensures that only pure hydrogen gas is produced on one side, while oxygen and any impurities are safely released on the other.

To optimize efficiency, PEM Electrolyzers often utilize catalysts like platinum or iridium oxide to facilitate faster reaction rates and reduce energy losses. Additionally, control systems monitor parameters such as temperature and pressure to maintain optimal operating conditions.

With its ability to produce high-purity hydrogen gas efficiently and reliably, PEM Electrolyzers have become increasingly important in various applications ranging from renewable energy storage to industrial processes.

How Proton Exchange Membrane (PEM) Electrolyzer Work

Proton Exchange Membrane (PEM) electrolyzers are a crucial component of hydrogen production systems. But how exactly do they work? Let's dive into the fascinating world of PEM electrolyzers!

At the heart of a PEM electrolyzer is a proton exchange membrane. This membrane acts as an electrolyte and separates the anode from the cathode. When an electric current is applied to the system, water molecules split at the anode, releasing protons (H+) and electrons (e-).

The protons travel through the membrane towards the cathode while electrons take an external path via a circuit. On their way to meet each other again at the cathode, these charged particles generate hydrogen gas by combining with one another.

To ensure high efficiency and performance, PEM electrolyzers require precise control of operating conditions such as temperature and pressure. Additionally, catalysts are used on both sides of the membrane to facilitate reactions.

Once set up properly, PEM electrolyzers can produce high-purity hydrogen gas that can be utilized in various applications like fuel cells for automobiles or industrial processes requiring clean energy sources.

Innovative companies like Gatechn New Energy Technology (Shanghai) Co., Ltd., are dedicated to developing advanced PEM technology for sustainable energy solutions. With continuous research and development efforts, we can expect even more efficient and cost-effective PEM electrolysers in years to come!

Applications for Proton Exchange Membrane (PEM) Electrolyzer

The Proton Exchange Membrane (PEM) electrolyzer has a wide range of practical applications across various industries. One of the key uses of PEM electrolyzers is in hydrogen production. The process involves splitting water molecules into hydrogen and oxygen gases, with the help of an electric current passing through the PEM membrane.

One major application is in renewable energy storage. PEM electrolyzers can be used to store excess electricity generated from renewable sources, such as solar or wind power, by converting it into hydrogen gas. This stored hydrogen can later be used to generate electricity when there is a high demand or when renewable energy sources are not available.

Another important application is in fuel cell vehicles. PEM electrolyzers play a crucial role in producing clean and sustainable fuel for these vehicles by generating hydrogen gas on board using water and electricity from the vehicle's battery system.

Additionally, PEM electrolyzers find use in industrial processes such as metal refining, chemical synthesis, and power-to-gas systems. These systems enable efficient conversion and storage of surplus electrical energy by transforming it into valuable chemicals or gases that can be utilized across various sectors.

The versatility of Proton Exchange Membrane (PEM) electrolyzers makes them invaluable for applications related to renewable energy storage, fuel cell vehicles, industrial processes like metal refining and chemical synthesis, as well as power-to-gas systems. Their ability to produce clean and sustainable fuels contributes significantly towards achieving a greener future while reducing reliance on fossil fuels

Conclusion

In this blog post, we have explored the basics of Proton Exchange Membrane (PEM) Electrolyzer and how it works. We learned that PEM electrolyzers utilize a proton exchange membrane to separate hydrogen and oxygen gases during the process of electrolysis. This technology is becoming increasingly popular due to its efficiency, flexibility, and environmentally friendly nature.

The working principle of a PEM electrolyzer involves passing an electric current through water to split it into hydrogen and oxygen gases. The protons are transferred across the membrane while electrons flow through an external circuit, resulting in the production of pure hydrogen gas at one electrode and oxygen gas at the other.

PEM electrolyzers find applications in various industries such as energy storage systems, renewable energy integration, power-to-gas projects, fuel cell vehicles, and more. Their compact size, rapid response time, high efficiency, and ability to operate under varying loads make them suitable for both stationary and mobile applications.

Gatechn New Energy Technology (Shanghai) Co., Ltd., is one company that specializes in manufacturing PEM electrolyzers with advanced features like stack modularity for easy scalability and intelligent control systems for optimized performance.

Understanding the basics of Proton Exchange Membrane (PEM) Electrolyzer opens up exciting possibilities for harnessing clean hydrogen as a sustainable energy source. As advancements continue in this field, we can look forward to even more efficient and cost-effective solutions that will contribute towards a greener future.

So whether you're interested in exploring renewable energy options or looking for ways to integrate hydrogen into your industrial processes or transportation sector—Proton Exchange Membrane (PEM) Electrolyzer technology holds great promise!