In the dynamic landscape of plastic manufacturing, Injection Molding Machine and PET Blowing Machine have emerged as transformative technologies, reshaping the way products are designed and produced. This article explores the evolving capabilities of these machines and their significant contributions to the plastic manufacturing industry.

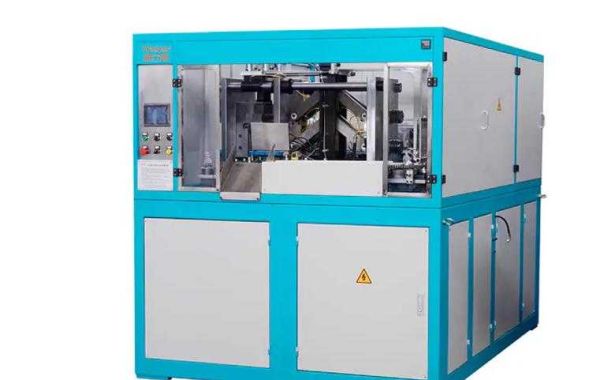

Injection Molding Machine:

The Injection Molding Machine stands at the forefront of plastic production, embodying efficiency and precision. This technology involves injecting molten plastic into a mold to produce a wide range of plastic products. Recent advancements focus on enhancing the speed and accuracy of the molding process, improving energy efficiency, and expanding the scope of materials that can be effectively processed.

One notable development is the integration of smart technologies into Injection Molding Machines. These innovations enable real-time monitoring of the manufacturing process, optimizing parameters such as temperature and pressure to ensure consistent product quality. The incorporation of artificial intelligence and machine learning algorithms contributes to predictive maintenance, minimizing downtime and increasing the overall efficiency of the production line.

PET Blowing Machine:

PET Blowing Machines play a pivotal role in the production of plastic bottles and containers, particularly in the packaging industry. The technology involves the transformation of preforms into finished products through a precise blowing process. Recent advancements in PET Blowing Machines focus on increasing production speed, improving energy efficiency, and enhancing the versatility of the machines to accommodate various bottle designs and sizes.

One notable trend in PET Blowing Machines is the development of energy-efficient models that reduce the environmental impact of the manufacturing process. Manufacturers are exploring innovative heating technologies, improved insulation, and optimized air compression systems to achieve higher energy efficiency without compromising the quality of the final product. Additionally, advancements in mold design contribute to greater flexibility, allowing for the production of unique and intricate bottle shapes.

Synergies and Applications:

The convergence of Injection Molding and PET Blowing technologies opens up new possibilities for manufacturers seeking comprehensive solutions for plastic product development. Integration of these processes allows for the creation of complex, multi-layered products with varying material properties. This synergy not only enhances the design flexibility of plastic products but also contributes to the development of lightweight and sustainable packaging solutions.

Sustainability Considerations:

As the plastic industry faces increasing scrutiny regarding its environmental impact, both Injection Molding and PET Blowing Machine manufacturers are investing in sustainable practices. This includes the exploration of biodegradable materials, the implementation of recycling technologies, and the development of energy-efficient machines. By aligning with global sustainability goals, the industry aims to address concerns related to plastic waste and resource consumption.

In conclusion, the evolution of Injection Molding and PET Blowing Machines signifies a paradigm shift in plastic manufacturing. Advancements in smart technologies, energy efficiency, and sustainability considerations are reshaping these machines, offering manufacturers unprecedented capabilities and flexibility. As the industry continues to innovate, the synergy between Injection Molding and PET Blowing technologies is likely to redefine the landscape of plastic product development, fostering a more sustainable and technologically advanced future.