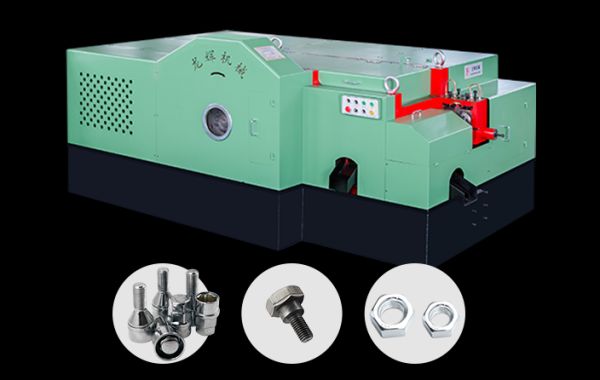

In the dynamic landscape of industrial machinery, the Cold Heading Machine stands as a versatile workhorse, revolutionizing metalworking and fastener production across diverse applications. This article explores the myriad sectors where Cold Heading Machines find application, showcasing their crucial role in shaping components that serve as the backbone of various industries.

Automotive Industry:

The automotive sector stands as a prime beneficiary of Cold Heading Machines, leveraging their capabilities for the production of essential fasteners. Bolts, screws, and rivets, foundational to vehicle assembly, undergo precision cold heading to ensure structural integrity and reliability. Moreover, Cold Heading Machines contribute significantly to the manufacturing of specialized engine components like studs and pins, where the cold heading process proves instrumental in maintaining required strength and durability under demanding engine conditions. Additionally, various components of a vehicle's suspension system, including nuts, bolts, and connecting rods, are efficiently produced using Cold Heading Machines, aligning with the sector's need for high-strength and durable parts.

Construction and Infrastructure:

Cold Heading Machines play a pivotal role in the construction and infrastructure sectors, offering efficient solutions for the production of fasteners crucial in joining and securing various components. Structural bolts, nuts, and anchors, fundamental to construction projects, are manufactured with precision using Cold Heading Machines. The reliability and strength achieved through the cold heading process make these components integral to the robustness of diverse structures.

Electronics and Electrical Components:

The electronics industry benefits significantly from Cold Heading Machines in the production of precision components. Connectors, terminals, and small fasteners used in electronic devices undergo the cold heading process to ensure dimensional accuracy and reliability. The ability of Cold Heading Machines to produce intricate and high-precision components aligns seamlessly with the demands of the ever-evolving electronics sector.

Consumer Goods and Appliances:

In the realm of consumer goods and appliances, Cold Heading Machines contribute to the manufacturing process by producing fasteners and components. From screws embedded in appliances to fasteners used in furniture, the versatility of Cold Heading Machines caters to the diverse needs of consumer goods manufacturing. The efficiency of the cold heading process ensures the reliability and functionality of everyday products.

Medical Devices:

The medical industry, with its stringent requirements for precision and reliability, finds Cold Heading Machines indispensable in the production of components for medical devices. Fasteners used in orthopedic implants, surgical instruments, and various medical equipment undergo the cold heading process to meet the high standards of the medical sector. The ability to consistently produce high-quality and precisely shaped components is crucial in this field.

Aerospace and Defense:

Cold Heading Machines play a critical role in the aerospace and defense sectors, where precision and durability are non-negotiable. Components such as fasteners, bolts, and specialized parts used in aircraft and defense systems undergo precision cold heading to meet the stringent requirements of these industries. The reliability and strength achieved through cold heading contribute significantly to the safety and functionality of aerospace and defense applications.

Sporting Goods and Recreation:

The manufacturing of sporting goods and recreational equipment benefits from the application of Cold Heading Machines. Components such as bolts, screws, and fasteners, essential for the durability and functionality of sporting equipment, are efficiently produced using cold heading technology. The robustness and strength achieved through cold heading contribute to the reliability of these products, ensuring they withstand the rigors of various sports and recreational activities.

Energy Sector:

The energy industry, encompassing both traditional and renewable sources, relies on Cold Heading Machines for the production of components used in power generation and distribution. Fasteners and specialized parts undergo cold heading to meet the specific demands of the energy sector. The reliability and efficiency of these components contribute to the overall stability and functionality of energy-related applications.

General Manufacturing:

Beyond specific industries, Cold Heading Machines find applications in various other manufacturing processes where the efficient production of high-strength, precision components is essential. From tools and machinery to everyday products, the versatility of Cold Heading Machines transcends industries, contributing to the production of components that form the foundation of modern manufacturing.

In conclusion, the Cold Heading Machine emerges as a linchpin in the manufacturing landscape, adapting seamlessly to the diverse needs of industries worldwide. Its role in efficiently producing high-quality, precision components is instrumental in shaping the functionality and reliability of products across automotive, construction, electronics, healthcare, aerospace, and beyond. As industries evolve, Cold Heading Machines continue to be a cornerstone in the journey towards efficient and reliable manufacturing processes.