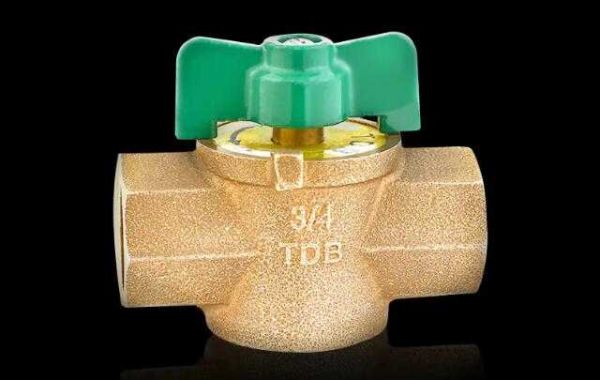

Brass Gas Valve Manufacturers are at the forefront of producing essential components that play a vital role in the safe and efficient operation of gas systems. Their focus on quality, innovation, and adaptability has led to the development of advanced brass gas valves that cater to a variety of applications and industries. This article delves into the key innovations and trends in brass gas valve manufacturing that are shaping the future of the industry.

One significant trend in brass gas valve manufacturing is the integration of advanced materials and coatings. Manufacturers are continuously exploring new materials and surface treatments that can enhance the durability and resistance of brass valves. These innovations can improve the valves' ability to withstand harsh conditions, such as extreme temperatures and corrosive environments.

In addition to material advancements, manufacturers are also investing in precision engineering and automation technologies. These tools allow for the production of brass gas valves with tight tolerances and consistent quality. Precision manufacturing ensures that the valves perform reliably and safely, meeting stringent industry standards and regulatory requirements.

Another area of focus for brass gas valve manufacturers is the development of smart valve technologies. Smart valves incorporate sensors and digital controls that enable real-time monitoring and adjustments. These valves can provide valuable data on gas flow and pressure, allowing for more efficient and proactive management of gas systems. Smart valves also enhance safety by enabling quick responses to potential issues.

Brass gas valve manufacturers are also exploring the use of additive manufacturing, or 3D printing, in their production processes. Additive manufacturing offers the potential for greater design flexibility and customization, allowing manufacturers to create valves with complex geometries and tailored features. This technology can lead to the development of brass gas valves with enhanced performance and efficiency.

Sustainability remains a key consideration for brass gas valve manufacturers. Many companies are implementing eco-friendly practices in their production processes, such as using recyclable materials and minimizing waste. Additionally, manufacturers are exploring ways to reduce energy consumption and emissions during production.

In conclusion, brass gas valve manufacturers are continuously pushing the boundaries of innovation to create products that offer enhanced performance, safety, and sustainability. By integrating advanced materials, precision engineering, smart technologies, and eco-friendly practices, manufacturers are contributing to the advancement of gas system operations across various industries. As the industry continues to evolve, brass gas valve manufacturers will play a critical role in shaping the future of gas system technology.