Recently, the growth of worldwide fishery and also tank farming is quick, and also the range of numerous freshwater and also saltwater tank farming ranches is additionally expanding. There is numerous sort of fish feed acquired on the marketplace, however, the majority of them have solitary nourishment and also blended high quality, which can not fulfill the everyday development demands of unique fish and also fish and shellfish. Just how to fix the nutrition material of fish feed has actually ended up being a migraine for tank farming proprietors.

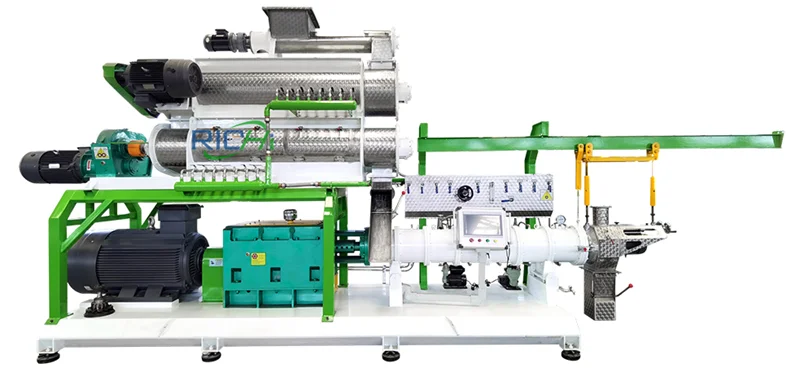

Fish feed pellets are generally made use of in modern-day farming fish farming to give the nourishment needed by fish and also enhance the atmosphere of fish ranches. A twin screw floating fish feed extruder machine is extensively utilized to generate the extruded feed.

There are numerous variables influencing the development of products, however, they are generally pertaining to the conditioning problems, the operating problems of the floating fish feed extruder machine, as well as the product buildings.

In the manufacturing of increased and also sinking feed, the solid result of extrusion ought to be damaged as well as the duty of conditioning needs to be boosted. This means the product can proceed to develop without creating a big level of development, as well as the sinking feed can be gotten. What are the attributes of the floating fish feed extruder machine?

1. The twin screw drifting fish feed assembly line can generate fish feed such as tilapia, gold trout, tropical fish, fish, shrimp, and so on 2. Drifting fish feed can not just enhance feed performance, however much more notably, farmers can see the consuming circumstance, prevent overfeeding, and also decrease feed waste.

3. The fish pellets made by this equipment can drift in the water for greater than 24 hrs.

4. The gelling level can get to 90%, and also the feed result can be enhanced.

The twin screw drifting fish extruder equipment supplies the adhering benefits for fish feed manufacturing:

1. Extrusion handling is when basic materials are refined under heat, high pressure, and also immediate ripening, incorporating transport, squashing, extrusion, blending, high-temperature sanitation, as well as molding.

2. It can refine thick, high-fat, as well as high-moisture resources.

Whether it is sinking feed or drifting feed, it will certainly not break down after saturating in water for 12 hrs. It can preserve the top quality of tank farming water and also lower the waste of feed.

The digestibility of starch, healthy protein, as well as various other materials, is enhanced. Solid extrusion can weaken some small cellulose, keratin, as well as various other compounds, as well as considerably enhance digestibility.

5. Exceptional palatability. The ended-up squeezed-out pellets have the features of permeability as well as also structure as well as generate some fragrant compounds, which promote the hunger of water pets as well as boost their feed consumption.

6. The application range of basic materials has actually been expanded. The twin-screw squeezing-out maker can refine products consisting of extreme water, oil, or cellulose right into various other kinds of marine products, which improves feed sources.

With the massive growth of the tank farming sector, the need for marine feed is obtaining greater as well as greater. The standard powdered formula feed, granular formula feed, as well as various other sorts of formula feed have the negative aspects of bad security in water, quick clearing up rate, simple reason feed loss, as well as water air pollution, which has actually ended up being progressively inappropriate for the growth of modern-day tank farming. Enhanced fish feed fixes these troubles, as well as an increasing number of aquaculture families and also feed manufacturing facilities set up extrusion feed handling equipment.

The drifting fish feed manufacturing line can properly generate numerous drifting fish feed as well as sinking fish feed. The floating time of the feed in water can be regulated by changing the development level of the tools to generate high-grade fish food with various drifting residential or commercial properties to adjust to various fish. The major device of the fish feed manufacturing line is a twin-screw floating fish feed extruder machine.

As the tools specialized in the manufacturing of drifting fish feed, whether the development level satisfies the needs of fish feed is the criterion that can show the efficiency of the tools. The completely automated fish feed device manufacturing line generated by RICHI Machinery is a specialist manufacturing device for drifting fish feed established by our firm according to market needs.

More information is on the website: Feed Pellet Machine For Sale

Shrimp Feed Pellet Machine

Or you can contact:

Whatsapp: +86 18574103366

Email: enquiry@richipelletmill.com