ball screw for automation has become the cornerstone of modern industry, revolutionizing manufacturing processes and increasing efficiency across various sectors. At the heart of this automation revolution lies precision engineering, with ball screws emerging as a crucial component in achieving accurate and reliable motion control.

The significance of ball screws in automation cannot be overstated. Unlike traditional screw or belt-driven systems, ball screws offer unparalleled precision and efficiency, making them indispensable in applications that demand exacting performance standards. Whether it's CNC machining, semiconductor manufacturing, or robotics, the ability to precisely control linear motion is essential for achieving consistent results and maximizing productivity.

One of the key advantages of ball screws is their ability to minimize backlash and positioning errors, ensuring that movements are executed with pinpoint accuracy. This is particularly important in applications where tight tolerances are required, such as high-speed machining or intricate assembly processes. By eliminating the play and slop associated with traditional drive systems, ball screws enable engineers to achieve levels of precision that were previously unattainable.

Moreover, ball screws excel in delivering high efficiency, thanks to their low friction design and smooth rolling motion. Unlike sliding contact mechanisms, which can suffer from frictional losses and wear over time, ball screws maintain their performance characteristics even after prolonged use. This not only improves the overall efficiency of automated systems but also reduces energy consumption and operating costs, contributing to a more sustainable manufacturing environment.

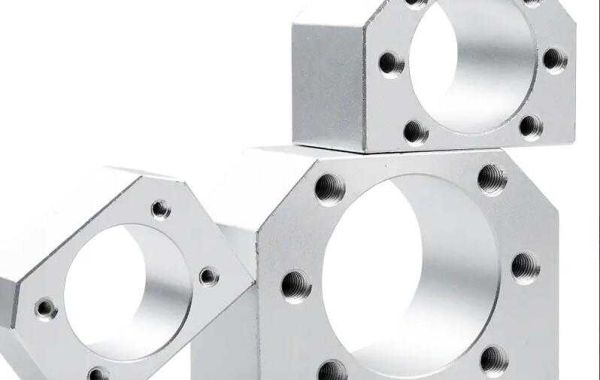

In addition to their precision and efficiency, ball screws offer versatility in design and application. They come in a variety of sizes, load capacities, and configurations, allowing engineers to tailor them to the specific requirements of each application. Whether it's a compact linear actuator for a medical device or a heavy-duty gantry system for automotive manufacturing, there's a ball screw solution available to meet the needs of virtually any automation project.

Furthermore, advancements in materials and manufacturing techniques continue to push the boundaries of what's possible with ball screws. Materials such as hardened steel, ceramic coatings, and high-performance polymers enhance durability and wear resistance, extending the lifespan of ball screws in demanding operating conditions. Meanwhile, precision machining processes ensure tight tolerances and consistent performance, even in the most challenging environments.

In conclusion, ball screws are a critical enabler of precision engineering in automation, providing the accuracy, efficiency, and versatility needed to drive modern manufacturing processes forward. As industries continue to adopt automation technologies to remain competitive in the global market, the importance of high-performance components like ball screws will only continue to grow. By leveraging the capabilities of ball screws, engineers can unlock new levels of productivity, reliability, and innovation, ushering in a new era of automation excellence.